A completely different approach to protecting concrete is to render it uninhabitable by the bacteria that convert the H2S into sulfuric acid in the first place. ConmicShield® is an EPA registered anti-bacterial additive that is added to fresh concrete as it is mixed. The product has been in use since 1996 and the concept of the basic antimicrobial dates back to the 60s. The breakthrough in the 90s was a means to stabilize the antimicrobial chemical in an aqueous solution, and then secondly stabilize it to be compatible with fresh highly alkaline concrete and lastly and most importantly ensure it remains active in the hardened concrete over the long term.

As a thin liquid the additive readily disburses throughout the concrete mix and ultimately bonds molecularly with all the concrete’s ingredients. This in turn prevents the colonization of acid producing aerobic bacteria on the concrete’s exposed surfaces for the life of the concrete. It is environmentally friendly and cannot leach out nor affect the chemistry of the waste water. It is safe and easy to dose and requires no special handling or safety precautions. In the hardened concrete, the additive is nontoxic to humans and animals, but permanently inhibits the growth of single-celled organisms like Thiobacillus.

It can be used in ready mix or precast operations and in many ways for repairs to existing corroded structures by means of centrifugally spinning, guniting (both wet and dry processes,) hand troweling, etc. a high performing technical repair mortars such as APM Permaform’s MS 10,000 and PL 8000. The antimicrobial admixture is not a lining or coating and will not peel or chip or wear off. It is as tough as the concrete. In new construction it is added by the concrete producer and as such no other action is needed in the field. Workers install the concrete / concrete products as if they were of ordinary composition. Properties of the fresh and hardened concretes are typically not affected by the addition of ConmicShield®. Colorants can be added at the plant to provide visual proof of the admixture’s presence. For repair projects involving mixed onsite mortars the ConmicShield® additive is simply added first to the batching water.

A brief summary is offered as to how the antimicrobial functions. Many antimicrobials kill bacteria by a chemical means. The chemical is consumed and therefore the antimicrobial is only effective for a period of time. ConmicShield® is based on a completely different technology. While it is a liquid chemical initially, it strongly bonds with every particle in hardened concrete and does not rely on a chemical reaction to kill bacteria.

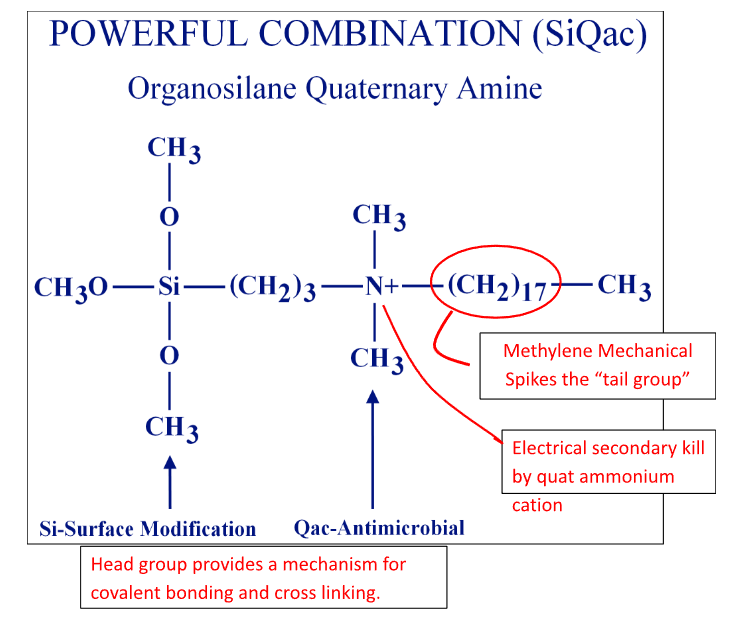

The active antimicrobial ingredient in ConmicShield® is generally categorized as a complex Quaternary Ammonium Silane (QAS) antimicrobial agent. It has been modified to function within cementitious materials like concrete and repair mortars. The manufacturing process is likewise a complex series of operations. When ammonium salts are reacted with certain organosiloxanes they form an integrated system, which can then be applied to almost any surface thus forming an invisible and durable antimicrobial protection. The QAS type molecule has what is considered a head group (containing the silane functional group and cationic ammonium moiety); and a tail group (hydrophobic – water shedding, carbon-chain). By virtue of these chemically distinct groups it is essentially a bi-functional molecule: with the head group providing a mechanism for covalent bonding and cross linking, and the cationic group tail group driving the interaction of the molecule with microbial membranes leading to the antimicrobial performance.

The figure on the next page provides the basic molecular structure.

The head group is known to react with surfaces by condensation thus forming a covalent linkage that is stable. This linking can occur both at a surface, and/or by cross linking with itself to form networks within concrete. Once the concrete is uniformly treated, it is the strongly anchored tail group that forms a rigid sharp mechanical structure that physically pierces & ruptures the cell membranes of microorganisms. The ionic association (soap bubble like thin cell membranes carry a negative charge) and lipophilic attraction, causes disruption and lysis of the microbial cell.

There is a very delicate balance of hydrostatic pressure and chemistry inside the cell which is most different and not compatible with the conditions outside the cell. Once punctured, the cell becomes inactive with death of the target bacteria resulting. With ConmicShield® distributed uniformly throughout the mix, all exposed surfaces provide a mode of antimicrobial activity. The positively charged tail group physically takes the form of long sharp mechanical spikes. There is no chemical exchange involved in the kill thus there is no chemical consumption and the effectiveness of the antimicrobial remains unaltered.