Concrete pipe has had a long history of use in sanitary applications

Concrete pipe has had a long history of use in sanitary applications. It was used in the Roman Aqueducts in 800 B.C. and can be found in pipe which was installed in the United States as far back as 1842 in Mohawk, New York.

Concrete corrosion is causing premature failure of structures

Deterioration of wastewater systems created by the effects of “Concrete Corrosion” is causing premature failure of structures resulting in expensive and disruptive repairs.

Even today, 78 years after the 1945 discovery of Microbial Induced Corrosion (MIC) by C.D. Parker, we continue to incorrectly refer to the corrosive deterioration of sewer pipe as “a H2S Gas Problem”. The primary problem for concrete in the sewer environment is Thiobacillus thiooxidans (concretivorous) – Latin for “concrete-eating”.

Mechanism of Concrete Corrosion

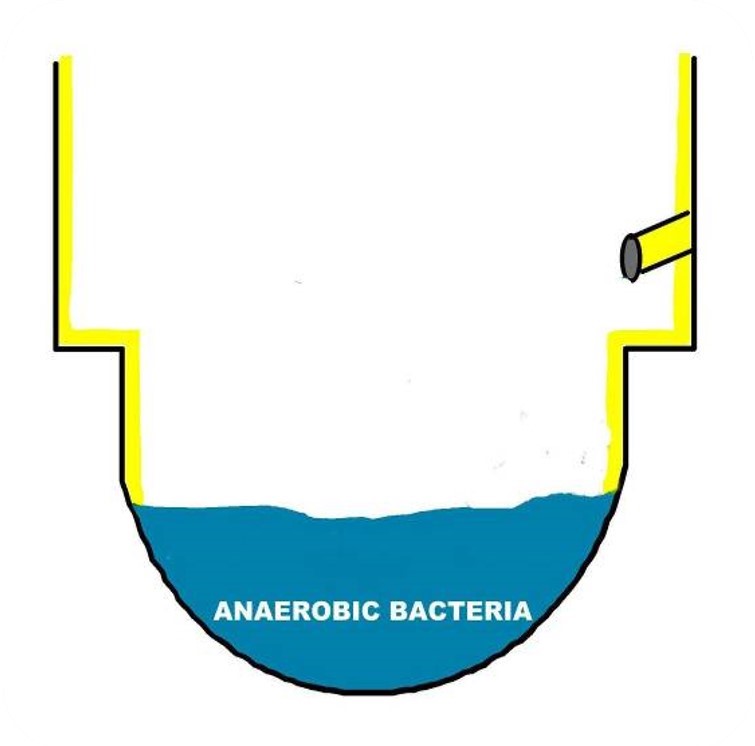

Stage 1

Anaerobic (non-air breathing) bacteria form in raw sewerage and produce H2S Gas. Factors contributing to rapid bacterial growth are temperature, retention time, high BOD (Biochemical Oxygen Demand).

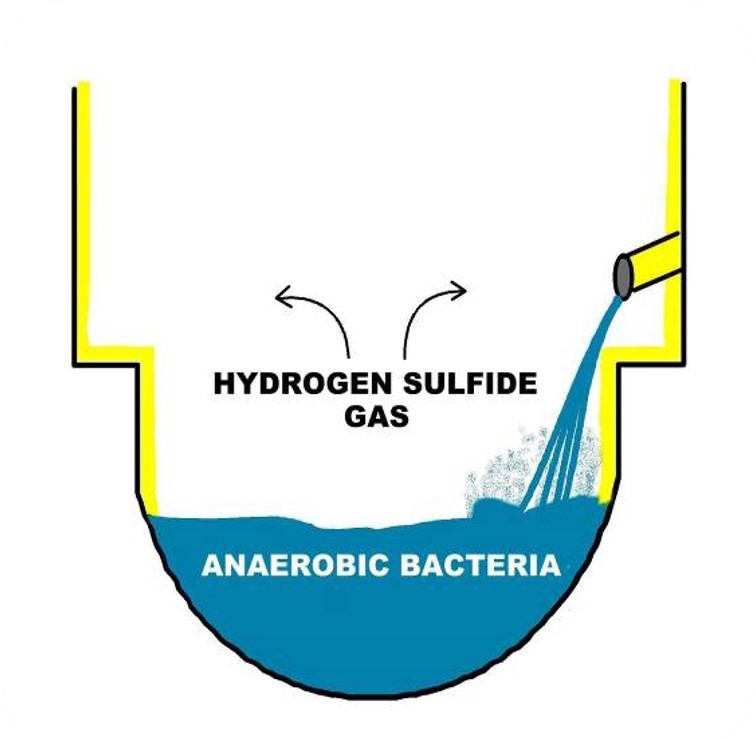

Stage 2

Turbulence from force mains, drop manholes, steep grade changes and pumping stations allow hydrogen sulfide gas (H2S) to release into the atmosphere in pipes and manholes.

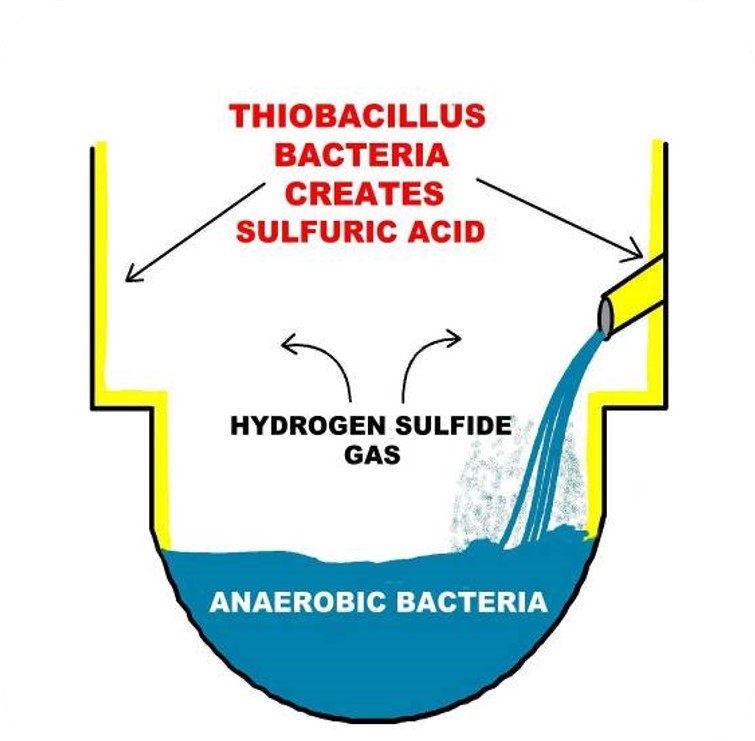

Stage 3

Hydrogen Sulfide gas (H2S) is converted into sulfuric acid (H2SO4) by the aerobic (air breathing) Thiobacillus bacteria that grows on the concrete surfaces above the wastewater flows.

Stage 4

Sulfuric Acid (H2SO4) quickly corrode the concrete, resulting in structural damage to pipes and manholes.

break the chain with Conshield

ConShield inhibits the growth of acid secreting bacteria by breaking the biological chain of events that produces the sulfuric acid.

ConShield® is a micro biostatic liquid concrete additive that is precisely dosed during the mixing phase to perform consistently, safely and effectively in each specific mix design produced by certified pre-casters, ready mix producers and shotcrete contractors. Once incorporated into the concrete mix design, imparts antimicrobial properties through out the finished concrete making the surface inhospitable to the grow of acid producing bacteria.